-

For whom:

HR Director, HR Generalist, HR-BP, HR Director

-

Target:

definition of the HR function in the processes of the organization

improving business efficiency

increase in personal efficiency

results

The trainees will know:

Strategic planning

Operational planning

Costs and their search

Process/Business Process Reengineering Tools

Resource usage

Planning and logistics management

Increasing production efficiency

Elements and approaches of lean manufacturing

What is R&D and the need for it

What is project management and the need for it

Tasks of investment planning

Course participants will be able to:

Build and manage strategy

Cascade strategy to the operational level

Develop strategic initiatives

Operational planning procedure

Cost reduction procedure

Modern approaches to optimization/reengineering of processes/business processes

Increase production efficiency

Apply elements and approaches of lean manufacturing

Formation and management of R&D

Build and develop a system of continuous improvements

Construction of a project office and implementation of project management

Manage change

Motivate to achieve results

Manage time to implement plans - find 25 hours in a day

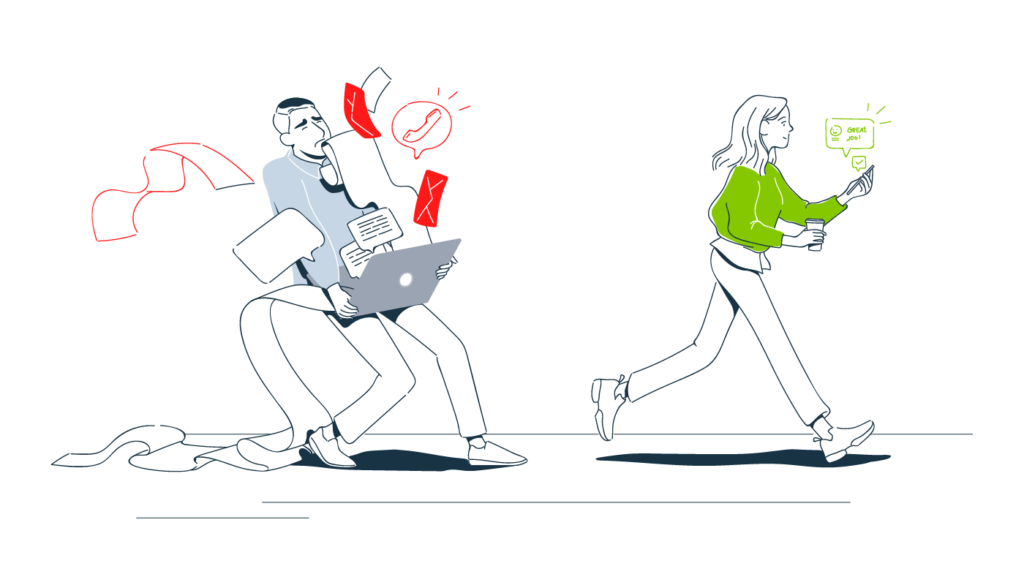

The operational efficiency of the company is the achievement of the best ratio between the resources involved and the final results of the work. A company that operates in this way does the same things faster, more efficiently, and at less cost than its competitors. This is not about simply saving resources, but about their optimal use.

Training program

Strategy

Planning/end-to-end planning

Increasing profits by reducing costs

Processes/Business Processes

Efficient use of resources and execution of operations

Logistics

Production efficiency

Lean Manufacturing and Lean Thinking

R&D

Construction, implementation and development of a system of continuous improvements

Project management and project office

Investment planning

Change management

organizational design

Motivation to achieve goals

Methods for improving personal effectiveness (time management for the implementation of plans)

Program schedule

1 day:

08.30 – 09.00 welcome coffee

09.00 – 09.10 introduction and brief overview of the program

09.10 – 10.00 strategy, its types, strategy change

10.00 – 10.45 work in groups. Case "Determining the company's strategy"

10.45 – 11.00 coffee break

11.00 – 12.00 HR strategy, strategic initiatives

12.00 – 13.00 work in groups. Case "Formation of the company's HR strategy"

13.00 – 14.00 lunch

14.00 - 14.40 work with costs - headcount optimization, cost optimization

14.40 - 15.45 work in groups. Case "Repair service of the plant"

15.45 – 16.00 coffee break

16.00 – 17.00 R&D

17.00 – 17.45 internal logistics

17.45 – 18.00 summing up the day

2 day:

08.30 – 09.00 welcome coffee

09.00 – 09.20 introduction to lean manufacturing

09.20 – 09.40 5S

09.40 – 10.45 elements of lean manufacturing Just in time, SMED, TPM, Poka-Yoke, kaizen, kanban, Andon, standardization, quality tools

10.45 – 11.00 coffee break

11.00 – 12.00 elements of lean manufacturing (continued)

12.00 – 13.00 value stream

13.00 – 14.00 lunch

14.00 – 15.00 Toyota system

15.00 – 15.45 TOS

15.45 – 16.00 coffee break

16.00 - 17.45 work in groups. Case "Mini bakery"

17.45 – 18.00 summing up the day

3 day:

08.30 – 09.00 welcome coffee

09.00 – 10.00 development, implementation and development of a continuous improvement system

10.00 – 10.45 group discussion on continuous improvement system

10.45 – 11.00 coffee break

11.00 – 12.00 business process reengineering

12.00 – 13.00 group discussion on business process reengineering

13.00 – 14.00 lunch

14.00 – 15.00 project management, mini projects, project motivation

15.00 – 15.45 group discussion on project management

15.45 – 16.00 coffee break

16.00 – 16.30 organizational design

16.30 – 17.00 investment planning

17.00 – 17.20 other tools to improve operational efficiency

17.20 – 17.45 personal efficiency improvement

17.45 – 18.00 summing up the day